COWLINGS____________

After spending a lot of time experimenting with plugs, moulds and vacuum forming I decided to go back to good, old fashioned balsa carving. It turned out to be a fairly simple but tedious process. It has taken about 8 hours to create each cowling.

__________________________

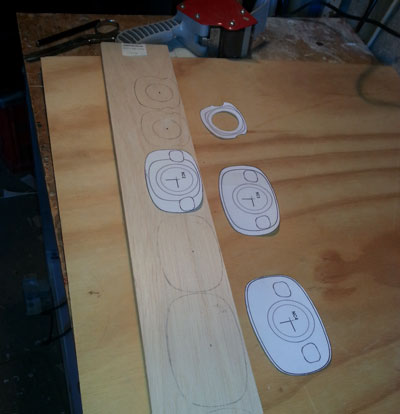

To start, I cut out the paper templates for the formers. It would also have been easy to trace them onto the balsa with carbon paper.

To start, I cut out the paper templates for the formers. It would also have been easy to trace them onto the balsa with carbon paper.

___________________

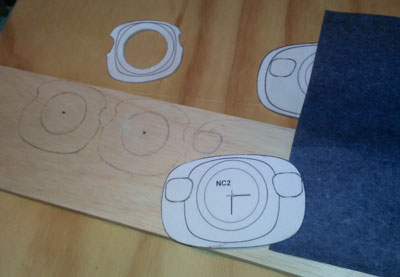

I used the carbon paper to mark out the air intakes. Carbon paper is getting hard to find however my local bulk stationary store still carries it. Carbon paper, white out... heading for extinction.

I used the carbon paper to mark out the air intakes. Carbon paper is getting hard to find however my local bulk stationary store still carries it. Carbon paper, white out... heading for extinction.

____________________

All layers cut out. I used a hole cutter to cut the nose ring from ply, I then picked off the outer layers of ply to leave the hard centre layer. This worked out well, it gave me a boundary to sand to.

All layers cut out. I used a hole cutter to cut the nose ring from ply, I then picked off the outer layers of ply to leave the hard centre layer. This worked out well, it gave me a boundary to sand to.

____________________

About an hour of shaping with a belt sander and hand sanding and I have the shape I'm looking for. Lycoming cowlings have a lot of curves and angles but with the use of electric sanders and the Dremel it wasn't to difficult. I was careful not to take any meat off the back former as the step is to add nacelle panels that will be shaped in.

______________________

Building up the cowling. I've cut panels with 45° sides as shown in the photo. I glued into position the top and side panels and the back former (engine F3). I did these first because they are at 90° to the front panel and allows we to get the alignments acurate. F3 is recessed so the cowl can be positioned accurately on the nacelle. (This will be explained in more detail as the build continues.)

Building up the cowling. I've cut panels with 45° sides as shown in the photo. I glued into position the top and side panels and the back former (engine F3). I did these first because they are at 90° to the front panel and allows we to get the alignments acurate. F3 is recessed so the cowl can be positioned accurately on the nacelle. (This will be explained in more detail as the build continues.)

__________________________

Sometimes the quickest and easiest way to form a shape is to go freestyle. Using a belt sander and careful not to take to much off, the cowling takes shape. Once it's close, it's down to hand sanding, fill where required and so on. I'll use the Dremel to clean out any excess material to lighten it and tidy up. Some of the sides are built up from scrap balsa. I hate waste.

Sometimes the quickest and easiest way to form a shape is to go freestyle. Using a belt sander and careful not to take to much off, the cowling takes shape. Once it's close, it's down to hand sanding, fill where required and so on. I'll use the Dremel to clean out any excess material to lighten it and tidy up. Some of the sides are built up from scrap balsa. I hate waste.

________________________

Finally, The cowlings are shaped. Wood putty is used to fill any gaps and sanded again. I've used a water based varnish, generously coated, to help harden the balsa. Later they will receive a fine sanding and finishing.

Finally, The cowlings are shaped. Wood putty is used to fill any gaps and sanded again. I've used a water based varnish, generously coated, to help harden the balsa. Later they will receive a fine sanding and finishing.

But before I can do anything else, I have to clean up the work shop... what a mess, saw dust and shavings everywhere.

__________________________

Next Twin Comanche Engine Nacelles

{jcomments on}