FUSELAGE________

FUSELAGE________

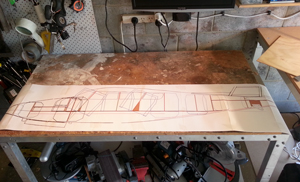

Finally, it's time to start the fuselage. The fuselage is the last major component to construct because I want to be able adjust the wing mounts to fit the wings. It would be too hard the other way round. Ideal everything will mate perfectly but we know that is not always the case. I've done all the printing of the formers and decks and now for the cutting.

______________________________

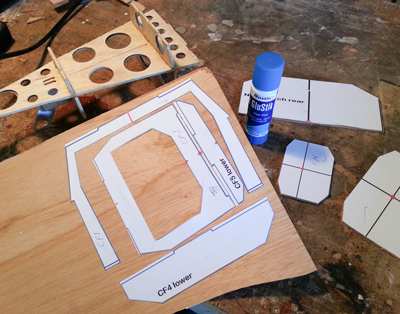

Once I've cutout the paper printouts of the formers I use a glue stick to attach them to the ply. Make sure you get the glue right up to the edges of the paper or the blade will flick the paper up and down making it hard ti follow the cut line. I believe you need an electric fret saw for a project such as this... without it cutting the ply is a long and tedious process and you will run the risk of loosing interest in your project.

___________________________

Don't waste your raw materials. Waste will make your project more expensive and will have you doing extra trips to the hardware to buy more materials. When I lay out my templates I try to get as mch out of each piece of material as I can.

______________________________

With the parts cut we can start fitting and gluing. This is when your work starts to reveal your goals. Where-ever I feel I can remove excess material from the build I will. Many RC aircraft builders will tell you that this much ply is overkill and the use of balsa would make it lighter. I agree that it would be lighter however ply gives a much greater strength and rigidity. Also, it's cheaper. My answer to the weight is simply to take away as much as I can without totally compromising the integrity. I have a set of whole saws that are ideal for the job.

With the parts cut we can start fitting and gluing. This is when your work starts to reveal your goals. Where-ever I feel I can remove excess material from the build I will. Many RC aircraft builders will tell you that this much ply is overkill and the use of balsa would make it lighter. I agree that it would be lighter however ply gives a much greater strength and rigidity. Also, it's cheaper. My answer to the weight is simply to take away as much as I can without totally compromising the integrity. I have a set of whole saws that are ideal for the job.

______________________________